About Gravure

Basics of the Gravure Printing Process

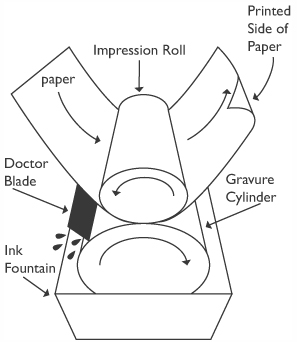

Gravure is small cells recessed into a cylinder that hold ink. The cylinder is washed with ink; a doctor blade removes the excess, leaving ink only in the cells. The ink is transferred to a substrate (paper, plastic, film, and more) using a rotary press.

Rotogravure, or gravure, is an old process. Building on earlier printing methods, modern gravure began in the late 19th century, and became widespread in the early 20th century. The popularity of the Sunday rotogravure section, which was filled with printed photographs, increased the use of gravure.

Today gravure printing is widely used in:

- Publication printing (magazines, newspapers, catalogs), where long runs at high speed are common. Gravure's remarkable density range makes it the best choice for fine art and photography

- Packaging printing, where printing on a variety of substrates is needed. Long runs are also common.

- Gravure is also used to print laminates, gift wrap, wallpaper, postage stamps, and the text on candies and pills, among other things.

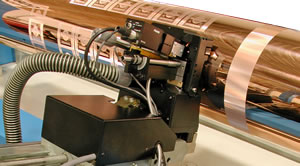

Cylinder being engraved

Cylinders

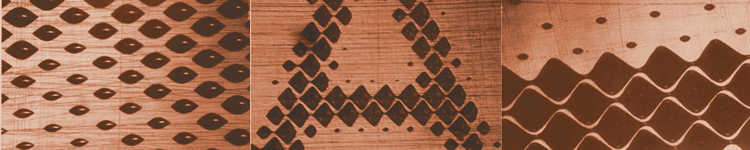

Cylinders for gravure have been made in several ways. First came chemical etch, followed by electro-mechanical (diamond cutting) and then laser etching. The latter two use digital images and controls.

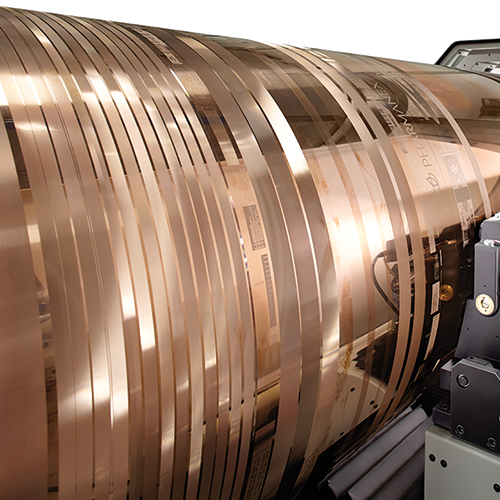

Gravure cylinders are extremely long-lasting. They are made of steel, coated in copper for engraving, then finished with chrome. When the cylinder is no longer needed, the chrome and copper can be removed and the steel base reused.

Because of the stable steel bases, gravure cylinders can be quite large. Some publication presses run 3 meter (9.84 feet) wide cylinders. Cylinders can also be extremely small: 16 inches wide or even less. Cylinder diameters can also vary from very small (2.5 inches or 64 mm) to very large (40 inches or 1,016 mm).

Extremely large engraver. This specialty machine is used to engrave laminates.

Advantages of Gravure

Each printing process has its strengths. Gravure has many:

Quality

"Gravure has fewer variables to control than other printing processes, ensuring more consistent print quality throughout a run." ("Gravure Process and Technology" 5)

Gravure provides "consistent color throughout a press run, even when that run consists of several million copies." ("Gravure Process and Technology" 7)

Gravure is a direct printing process: the image on the cylinder is printed directly to the substrate. This results in better ink laydown and thus a more faithful image rendering.

Versatility

Image data wrapped around the cylinder can be continuous, so no plate seam shows, such as in wall paper or gift wrap.

Gravure printing routinely uses a wide variety of substrates:

- Publication printing: Very thin paper, coated paper

- Packaging printing: Cardboard, plastic film, aluminum foil, laminates, vinyl, non-porous materials

Ink

The depth and size of engraved cells determines the amount of ink that can be put on the substrate. Gravure printing can lay down more ink than other processes.

Productivity

Gravure presses run at high production speeds: 3000-3300 feet per minute.

Cylinders are extremely durable. Print runs of 2 million to 3 million from one cylinder set are common.

The diamond cutting tool (the engrave head) can cut at speeds of up to 10,000 cells per second. Special applications use cutting speeds much lower, such as 2000 cps or even lower.

For more information

For more information on Gravure, we recommend contacting GAA, the Gravure Association of the Americas

Since 1980, Ohio Gravure Technologies has been a leader in designing machines for gravure. Constant innovation in hardware and software has resulted in sophisticated tools for the gravure printing industry. For more information about how our highly accurate gravure solutions can help with your application, please contact us.

Works Cited

"Rotogravure." Wikipedia, The Free Encyclopedia. 29 Nov 2009, 22:24 UTC. 9 Dec 2009

Gravure Process and Technology. Versailles, KY: Gravure Education Foundation and Gravaure Association of America, 2003. Print

ABOUT US

OHIO Gravure Technologies in Dayton, Ohio USA designs and manufactures advanced equipment for the global gravure printing market. The Engineering, Software Development, and Manufacturing groups work to provide innovative solutions to improve quality and productivity, such as the award-winning Hybrid Engraving System. Our engineering specialty since 1980 is our sub-micron accurate cutting system (Vision engrave head). We provide installation and support for our electromechanical engravers and the prepress layout software Collage for gravure printing.

20-Jul-2023

SERVICE

PRODUCTS

CONTACT

Ohio Gravure Technologies Inc

4401 Lyons Road

Miamisburg Ohio USA 45342

phone +1 937.439.1582

email

Follow us on Facebook

Follow us on Facebook