Engrave Head Refurbishment

344 Billion – that’s a quick calculation* of the number of cells your engrave head has cut over the last 5 years. OHIO GT offers an engrave head refurbishment program to reinvigorate your current head to like-new condition and performance.

The refurbishing program actually consists of two important pieces: the head refurb itself and a loaner engrave head. The loaner head allows you to continue your production while the original head is re-conditioned. While you continue cutting cylinders, OHIO’s factory-technicians review your original head and get to work making it as good as new.

The original head is disassembled, cleaned and inspected. Parts that are tired are replaced with new. Control electronics are also evaluated since they are an integral part in the engrave head performance. The head is then re-assembled and sent to the lab for a full set of tests prior to the actual tuning. When tuning is completed, the head is painted and returned to you with the same warranty as a brand new head.

Refurbishing a 20+ year old head

Refurbishing a 20+ year old head

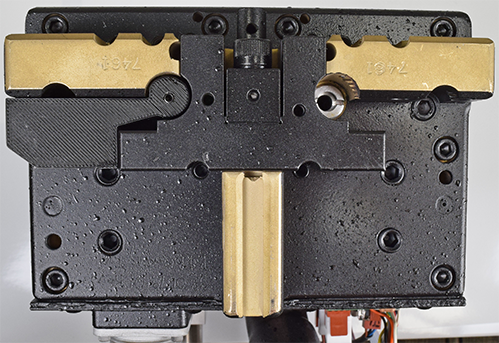

These pictures tell the story of an engrave head before and after refurbishment.

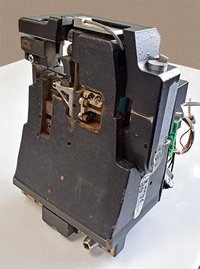

This head is a VISION 1, running at 4500 cells/second. It shipped from OHIO in 1997 on an M820 engraver and came back home after 20 years of operation.

As you can see, it shows signs of its age: missing parts, lower air nozzles restricted by dust, and a stylus arm that shows significant wear.

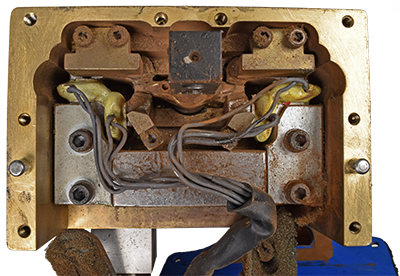

Once it was cracked open, the interior showed two decades of accumulated dust and corrosion.

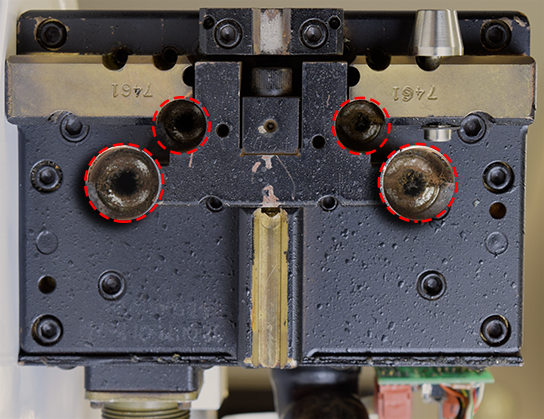

The air nozzles are nearly blocked (picture has been enlarged and lightened for easier viewing)

The interior of the engrave head showing years of dust, dirt, and rust build-up

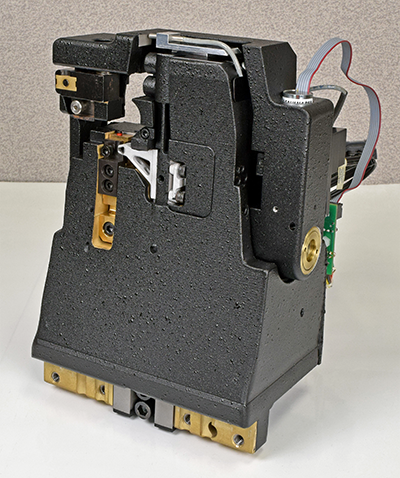

It is easy to see the groove cut into the stylus arm by years of engraving.

Making it like new

Making it like new

Head refurbishment for this unit included:

• Complete disassembly

• A thorough cleaning

• Media blasted to remove surface corrosion and paint

• Stylus arm replaced

• Damping material replaced

• Shoe assembly rebuilt, including a new drive motor

• Internal clamps and mounting hardware replaced

• Stylus position sensor replaced

• Missing smaller parts replaced

• New Air Filter added to the lower air nozzles

• New paint

• A complete suite of engraving tests

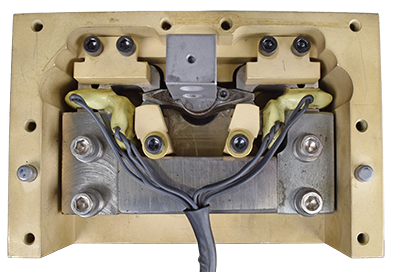

The new filters for the air nozzles were added to the engrave head (In this picture, the right filter is removed)

A sparkling clean inside after the refurbishment

The stylus arm has lost its groove (with a new stylus arm)

This head required significant work, but when finished, it is ready to tackle the next 344 billion cells – or more! The refurbished head has the same warranty as a brand new head at a considerably lower price.

* Calculated using 0.75m2 engraved area per cylinder, 70 l/cm screen, 2500 cylinders per year for 5 years.

When to refurbish your engrave head

We don't recommend waiting 20 years before sending an engrave head back to us for refurbishment. Over time, the performance of the head can degrade. If the working environment contains dirty air, this can significantly impair performance. We recommend a head refurbishment every 3 to 5 years.

How to proceed?

Please contact your local sales/service agent to request an RMA (Return Material Authorization) quote with shipping instructions. If you do not have a spare engrave head, please ask your local agent about the possibility of a loaner engrave head. Generally loaner heads are available through the agent who arranges the head refurbishment or repair. The number of loaner heads is limited. Loaner heads are available on a first-come first-served basis. Specialty tunes are not available on loaner heads.

08282018

ABOUT US

OHIO Gravure Technologies in Dayton, Ohio USA designs and manufactures advanced equipment for the global gravure printing market. The Engineering, Software Development, and Manufacturing groups work to provide innovative solutions to improve quality and productivity, such as the award-winning Hybrid Engraving System. Our engineering specialty since 1980 is our sub-micron accurate cutting system (Vision engrave head). We provide installation and support for our electromechanical engravers and the prepress layout software Collage for gravure printing.

20-Jul-2023

SERVICE

PRODUCTS

CONTACT

Ohio Gravure Technologies Inc

4401 Lyons Road

Miamisburg Ohio USA 45342

phone +1 937.439.1582

email

Follow us on Facebook

Follow us on Facebook