The TIFF Workflow

Collage allows you to use TIFF files in two ways: input and output.

- Create the job with a TIFF image, either a one-up or a fully-stepped-and-repeated image. Apply Collage's quality enhancement tools for the best possible output results. Enter the output parameters for your engraver.

- Output TIFF for an engraver. Collage supports TIFF direct engraving for Gravostar or Hell engravers.

TIFF Direct Engraving for Gravostar or Hell engravers

Hell engravers require TIFF images and the Collage Hell Output module creates the images and any support files. TIFF images are created at the engrave resolution specified in Collage.

TIFF output from Collage is available for Hell engravers and Hell or Gravostar engravers with a DTG front-end.

The Disadvantage of the TIFF Workflow

For the highest quality engraving and most efficient workflow, we recommend PDF or PostScript instead of TIFF. (This is especially important when using Hybrid Engraving. )

Why?

Best Quality = High Resolution = Large File;

Low Resolution = Small File = Inferior Results

Quality Issues

Typically, a TIFF image is created at 300 dpi. This resolution is sufficient for CT data but not usually for small text. Text at 300 dpi can be unacceptable, especially small text, reverse text, Kanji text or the like.

Typically, a TIFF image is created at 300 dpi. This resolution is sufficient for CT data but not usually for small text. Text at 300 dpi can be unacceptable, especially small text, reverse text, Kanji text or the like.

If the TIFF resolution is increased to improve the quality of text, the file size increases by a factor of four — doubling the image resolution produces quadruple the pixels. For example:

TIFF at 300 dpi = 24 MB

TIFF at 600 dpi = 96 MB

For line work, especially text, a resolution of 1000 dpi to 2000 dpi is recommended. Some specialty work (stamps, securities) may require 4000 dpi or more. TIFF files at these resolutions may be impossible: the maximum size of TIFF files is 2 gigabytes.

The poor quality of text in TIFF images with standard gravure engraving can be so unsatisfactory that jobs may be moved to other printing methods. Remember that with a 300 dpi image, pixels on a 300 x 300 grid are used to create the image. For small text, the result can be hard to decipher.

For the Highest image quality, use PDF — In all ways, a PDF workflow produces higher quality. CT data is retained in its original format and resolution. Text, fine line work, and even vignettes are all stored mathematically until output. Note: PostScript has similar advantages, but PDF is preferred as a more modern robust format that is continually updated.

Efficiency

From design to printed product, a package moves through several steps: files are created, transferred, output, and stored. Each step takes time, and larger file sizes take longer, reducing productivity.

From design to printed product, a package moves through several steps: files are created, transferred, output, and stored. Each step takes time, and larger file sizes take longer, reducing productivity.

A large file takes longer to transfer over a network or write to a DVD; longer to load in a computer for visual proofing, longer to print on a proofing device; and longer to process for output. Storing large files for later remakes may be so time-consuming or expensive that it doesn't get done. To increase productivity, working with smaller file sizes is critical. Tiff files are generally much larger than PDF files.

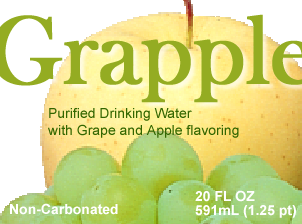

For example, consider this image's size when saved as Tiff and as PDF:

TIFF: 1.88 MB

PDF: 890 KB

Full-Up versus One-Up

If a TIFF workflow is required, an important consideration for file size is which workflow is used.

If a TIFF workflow is required, an important consideration for file size is which workflow is used.

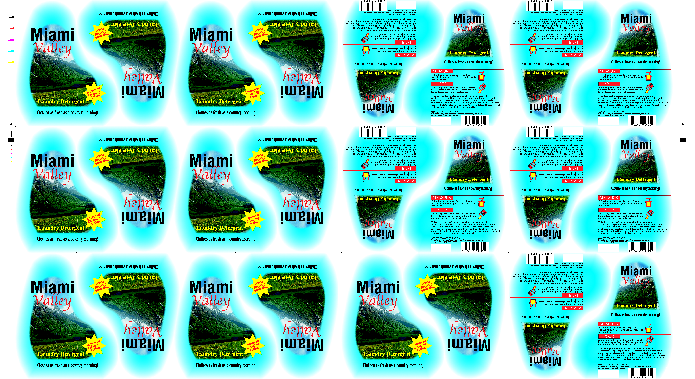

In the Full-Up Workflow, the fully stepped-and-repeated image is created on a design computer and saved in TIFF format. These images can be extremely large. Moving these files from design computer to output device, processing for output, and archiving takes time. The more time required for a job, the fewer jobs get done.

A more efficient TIFF workflow is for the designer to create a one-up image which is sent to Collage where the packaging layout is done. Because only the single one-up image is stored in the job, the file size is much smaller. Transferring, outputting, and processing are all faster, resulting in higher job throughput.

A more efficient TIFF workflow is for the designer to create a one-up image which is sent to Collage where the packaging layout is done. Because only the single one-up image is stored in the job, the file size is much smaller. Transferring, outputting, and processing are all faster, resulting in higher job throughput.

However, because TIFF is a raster format and PDF is vector, even a one-up TIFF file is larger than a one-up PDF file. For example:

| PhotoShop image | Format | Resolution | Size |

|---|---|---|---|

PSD 5.83 MB |

TIFF | 300 dpi | 24.03 MB |

| TIFF | 600 dpi | 96.11 MB | |

| PostScript | -- | 6.76 MB | |

| -- | 727 KB |

PDF for High Quality and High Productivity

For the best quality, and the greatest productivity, use PDF as the input image, ripped in the Xitron RIP, and layout in Collage.

ABOUT US

OHIO Gravure Technologies in Dayton, Ohio USA designs and manufactures advanced equipment for the global gravure printing market. The Engineering, Software Development, and Manufacturing groups work to provide innovative solutions to improve quality and productivity, such as the award-winning Hybrid Engraving System. Our engineering specialty since 1980 is our sub-micron accurate cutting system (Vision engrave head). We provide installation and support for our electromechanical engravers and the prepress layout software Collage for gravure printing.

20-Jul-2023

SERVICE

PRODUCTS

CONTACT

Ohio Gravure Technologies Inc

4401 Lyons Road

Miamisburg Ohio USA 45342

phone +1 937.439.1582

email

Follow us on Facebook

Follow us on Facebook