QuickCell™ Interactive System

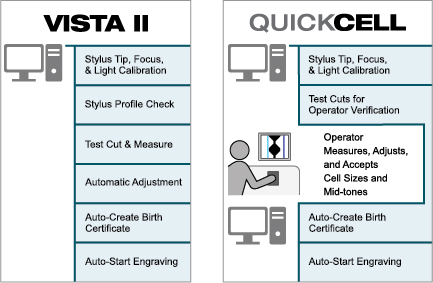

The Vista system provides a robust automatic test cut capability for the Spectrum. However, some situations require operator involvement in the setup process. For these customers, Ohio Gravure Technologies has developed the QuickCell setup system, exclusive to Spectrum and Prism Prime engravers.

QuickCell provides for more operator interaction, allowing the operator to quickly verify cell sizes.

With the QuickCell system, the camera focus and lighting are automatically adjusted and test cuts made, then the cells are displayed on-screen for the operator to review sizes without stopping cylinder rotation.

Adjustments are made using the touchscreen to move the cursors. During this time, the cylinder never stops turning, and if adjustment is needed, the next cut happens immediately with no waiting. The process is very fast.

Cylinder through-put is much faster than manual test cuts and similar to automated setup, and correct cell sizes are guaranteed with the operator involvement. After the operator accepts the test cut settings, the engraver automatically advances the carriage and begins cutting the job.

For customers running automated lines, the Vista system frees the operator for other tasks. Vista automatically measures test cuts, adjusts cell sizes as needed, performs Stylus Profiling, and starts engraving: all without operator intervention.

Both systems use Ohio GT’s advanced technology to automatically focus and calibrate the camera, automatically start engraving the job, and create Cylinder Birth Certificates at job completion.

Vista is optimized for automation and QuickCell is optimized for speed and operator verification.

Available on Spectrum and Prism Prime engravers.

Watch a video about QuickCell

QuickCell is a trademark of Ohio Gravure Technologies

ABOUT US

OHIO Gravure Technologies in Dayton, Ohio USA designs and manufactures advanced equipment for the global gravure printing market. The Engineering, Software Development, and Manufacturing groups work to provide innovative solutions to improve quality and productivity, such as the award-winning Hybrid Engraving System. Our engineering specialty since 1980 is our sub-micron accurate cutting system (Vision engrave head). We provide installation and support for our electromechanical engravers and the prepress layout software Collage for gravure printing.

20-Jul-2023

SERVICE

PRODUCTS

CONTACT

Ohio Gravure Technologies Inc

4401 Lyons Road

Miamisburg Ohio USA 45342

phone +1 937.439.1582

email

Follow us on Facebook

Follow us on Facebook