The Collage Workflow

Collage offers a simple workflow: from your design system to Collage to your engraver.

Click on part of the workflow below to see more information.

Input - The Design Part of the Workflow

Using the correct tool for the job is always important. The standard for packaging design work today is the Adobe Creative Suite (PhotoShop, Illustrator, InDesign and more). While these may include options or add-ins to do step-and-repeat, this requires the creative designer to be an expert in gravure output, which can be problematic. It is becoming more common, and Collage can be used with a Full-Up image: you can add Collage quality enhancement (gamma, sharpness, Hybrid) and set the output parameters.

Using the correct tool for the job is always important. The standard for packaging design work today is the Adobe Creative Suite (PhotoShop, Illustrator, InDesign and more). While these may include options or add-ins to do step-and-repeat, this requires the creative designer to be an expert in gravure output, which can be problematic. It is becoming more common, and Collage can be used with a Full-Up image: you can add Collage quality enhancement (gamma, sharpness, Hybrid) and set the output parameters.

The image from the design system can be a one-up (a single image to be stepped and repeated in Collage) or a full-up (the image is stepped-and-repeated on the design system), exported as Tiff, PostScript or PDF. Note that importing a PDF or PostScript into Collage requires the Xitron RIP. Learn about the Tiff workflow

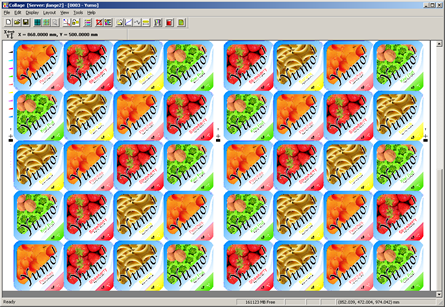

Layout in Collage

Layout in Collage

Collage excels at creating layouts for packaging gravure. It is simple to step-and-repeat an image, to use multiple images, even images of different sizes all on the same canvas, add gutters, bleeds, and marks.

Even when the step-and-repeat is done on the design system, you can use Collage tools to improve the final printed results: gamma, sharpness, Hybrid (optional).

Entering all the parameters for output (screens, angles, and more) is not only simple, but Collage's productivity tools, such as the Defaults Editor, remove operator error.

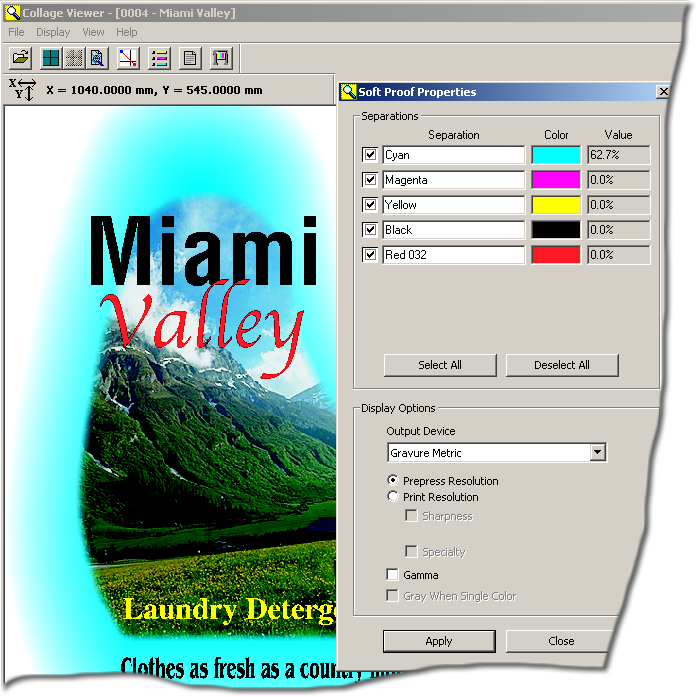

Proof before Committing to Copper

Collage offers several ways to proofing a job, and all are included in Collage: not separate programs.

On-screen Proofing — Use Collage's on-screen proofing to check the job before committing to copper.

On-screen Proofing — Use Collage's on-screen proofing to check the job before committing to copper.

View all colors or only some colors. Zoom up to the pixel level. You can even check the trapping done on the design computer to be sure it's correct for the printing process to be used.

Use either prepress resolution (as seen on the design system) or engrave resolution -- see exactly what will be engraved. Turn on gamma, sharpness or Hybrid. Even measure pixel densities.

Digital Proofing with the Job Viewer — With the Collage Job Viewer, a job can be previewed on any Windows computer by anyone: no need to have Collage. The customer can view the job exactly as it will be output, including checking the output parameters. All the on-screen proofing capabilities of Collage can be used, and the job can even be printed for a hard copy.

Digital Proofing with the Job Viewer — With the Collage Job Viewer, a job can be previewed on any Windows computer by anyone: no need to have Collage. The customer can view the job exactly as it will be output, including checking the output parameters. All the on-screen proofing capabilities of Collage can be used, and the job can even be printed for a hard copy.

Wide Format Proofing — Printing the job on your color wide-format printer is included in Collage -- no extra modules to purchase. Proof the entire job, or proof only certain parts of the job. Print all colors or only certain colors of the job. Collage supports any Windows-compatible proof device.

Wide Format Proofing — Printing the job on your color wide-format printer is included in Collage -- no extra modules to purchase. Proof the entire job, or proof only certain parts of the job. Print all colors or only certain colors of the job. Collage supports any Windows-compatible proof device.

Customer Approval

Collage provides two ways for you to obtain customer approval of the job before engraving begins: PDF files and the Collage Job Viewer.

PDF — Did you know you can print a PDF of a Collage job? Just install a program to create PDF files on the Collage computer. Then print the Collage job, selecting PDF as the printer. You can print the entire job, a single separation, a close-up of an area. Anything that you can print to a physical printer, you can print to a PDF file. The problem with this solution is that high quality PDFs are very large and not easy to move around. And when the PDF file size is low enough to email to the customer, the quality may be too low to see detail.

Collage Job Viewer — Collage includes the Job Viewer as part of the Collage Archive Manager. When a job is complete, create an archive with the Job Viewer. The archive can be sent to the customer via CD, DVD, or over the internet. At the customer site, they can view the job in a limited version of Collage on any PC. The customer doesn't even need to install any software on their PC: the Collage Job Viewer is contained in the archive.

Collage Job Viewer — Collage includes the Job Viewer as part of the Collage Archive Manager. When a job is complete, create an archive with the Job Viewer. The archive can be sent to the customer via CD, DVD, or over the internet. At the customer site, they can view the job in a limited version of Collage on any PC. The customer doesn't even need to install any software on their PC: the Collage Job Viewer is contained in the archive.

The customer can zoom up and down, view one or more separations, measure density values and distances, and even print to a local printer set up on the customer's PC. No editing of the job can be done in the Job Viewer.

Output to any engraver

Of course Collage jobs can be sent to any OHIO engraver, Daetwyler Gravostar engraver, and old OEE engraver. Whether you have a new Spectrum or Prism, an HS or D machine, or an old 700 or 800, the Collage software can create jobs.

Note: The RTI or embedded software must be at the same version as Collage or can be higher.

With the Collage Hell Output module add-in, you can output to any Hell or DTG-driven Hell engraver with HelioDisk v5.

ABOUT US

OHIO Gravure Technologies in Dayton, Ohio USA designs and manufactures advanced equipment for the global gravure printing market. The Engineering, Software Development, and Manufacturing groups work to provide innovative solutions to improve quality and productivity, such as the award-winning Hybrid Engraving System. Our engineering specialty since 1980 is our sub-micron accurate cutting system (Vision engrave head). We provide installation and support for our electromechanical engravers and the prepress layout software Collage for gravure printing.

20-Jul-2023

SERVICE

PRODUCTS

CONTACT

Ohio Gravure Technologies Inc

4401 Lyons Road

Miamisburg Ohio USA 45342

phone +1 937.439.1582

email

Follow us on Facebook

Follow us on Facebook