New Engraver Features

We are continually adding enhancements and new features to our product line. Some features are optional. Contact us for more information. Look here for new features in Collage

Vertex Stylus Monitoring System – Prism, Spectrum, and HS-2-Spectrum Engravers

Diamond stylus wear over time with the stylus angle increasing with wear. Additionally, chips will occur in the stylus. Both of these conditions reduce the cell volume as compared to a new stylus. Now, factor in copper that can vary and affect the cell size, and you quickly see the need to monitor the volume of the cell and not the width of the cell.

OHIO's Vertex Stylus Monitoring System considers all these factors when performing test cuts on the Spectrum or Prism. Minute adjustments are made to cell and channel widths to compensate for variations and produce the correct cell volume for the specific cell. VSM adjusts the highlight cell and the mid-tone cells to achieve consistent engraving and thus printing results.

Linear Drive – Prism

The Prism will soon have a linear drive for carriage motion, replacing the servo-motor and ballscrew. This new to the Prism feature has been used on the Spectrum engraver for many years. It offers high-precision and greater flexibility than a standard motor. This feature will be standard on both Prism and Prism XL machines.

Greater Circumference – Prism

The Prism is being re-designed for greater cylinder capacity, with a maximum circumference up to 1500mm, a 200+mm increase over current Prism engravers. The current capacity is just not quite enough according to our customers, so we listened and bumped up the size.

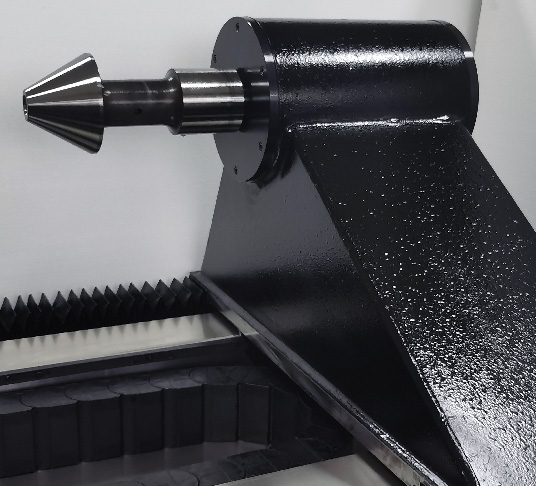

Heavy Tailstock – Prism

Another item requested by customers is a true, dual 3-jaw chuck system. Once again we listened and now offer a tailstock using integrated bearings rather than a live-center. Users can have the ability to correct cylinder run-out on both ends, whether shafted or hollow cylinders. For those with only hollow cylinders, a cone is mounted onto the taper of the tailstock shaft, just like the current headstock. For those with a mix of hollow and shafted cylinders, arbors are inserted into the chucks to accommodate hollow cylinders. |

|

New Embedded PC – All UNIX-based Engravers

OHIO recently began equipping all our engravers with a new embedded PC. This much smaller computer provides greater performance while taking up less space. With the new PC comes a refreshed operating system offers support for future features being developed.

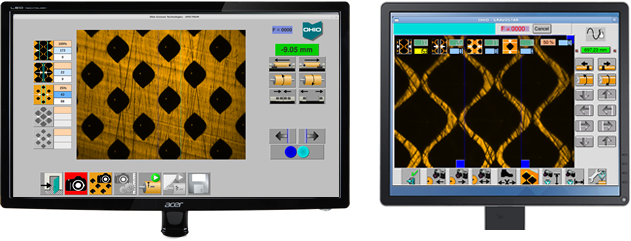

Redesigned User Interface

With the wide-screen, high-resolution monitors now standard on Spectrum, Prism and the GS HS Upgrade to Spectrum Controls, our designers took the opportunity to redesign the icon-based user interface. The workflow has been simplified and clarified and some pages will look every different. For example, here is the VISTA Cell Measure page:

The icons are now more detailed, sharper, more attractive, and we hope more easily understood. For example, here are a few icons, both old and new:

Old icon |

New icon |

Old Icon |

New Icon |

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

Ethernet Camera

The head camera has been changed to an Ethernet camera instead of the old Firewire camera. It is more reliable and provides sharper images. This camera is on all new Spectrums and Prisms. Upgrades are available for older Spectrums and Prisms, and for GS HS engravers upgraded to Spectrum Controls.

The head camera has been changed to an Ethernet camera instead of the old Firewire camera. It is more reliable and provides sharper images. This camera is on all new Spectrums and Prisms. Upgrades are available for older Spectrums and Prisms, and for GS HS engravers upgraded to Spectrum Controls.

Semi Automation

The Engraver does significant portions of the process without operator involvement. This includes cylinder face length verification (End Seeking), cylinder run-out verification (TIR measurement), head positioning for production engraving and engraving start. If specified in Collage job, a second test-cut is automatically performed. These are options for new Spectrum and Prism Prime

Sequenced Engraving

Also called "over-engraving." Both Collage and engraver embedded software have been enhanced to make Sequenced Engraving a better project. Now, the engraver job list only displays the first cylinder of a sequence. When that cylinder is selected, all cylinders in that sequence are automatically downloaded. Various positional data is not reset for sequenced cylinders, to ensure registration. See the CIB about Sequence Engraving

Also called "over-engraving." Both Collage and engraver embedded software have been enhanced to make Sequenced Engraving a better project. Now, the engraver job list only displays the first cylinder of a sequence. When that cylinder is selected, all cylinders in that sequence are automatically downloaded. Various positional data is not reset for sequenced cylinders, to ensure registration. See the CIB about Sequence Engraving

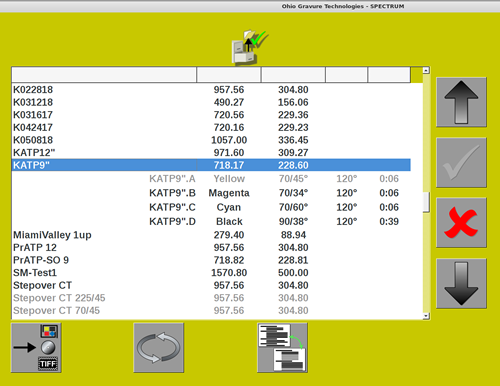

Job List on Engraver

The Job List on the engraver now shows the upper level Job ID as a folder name. Click on the folder name to see all the cylinders in the job. This change greatly improves the usability of the Job List, which previously could grow to hundreds of individual cylinders at large plants. See this CIB about Sequence Engraving for more information on using the Job List.

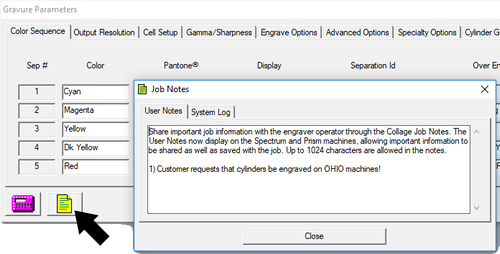

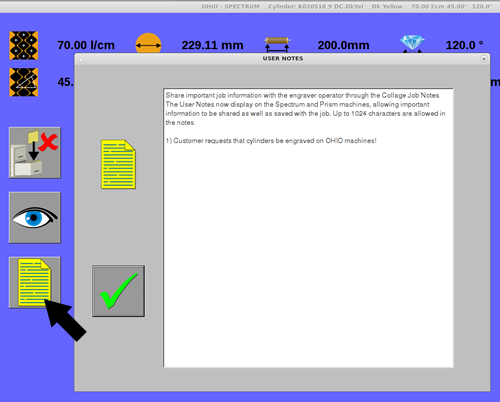

Job Notes now Shared with Engraver

The Collage operator can add notes to the job ....

... that can then be viewed on the engraver.

Limited to 1024 characters.

Engraving from USB Drive

You can now engrave jobs from a USB drive, not just from a CD. Recent Spectrums and Prism engravers have a USB port on the top of the machine. Older machines can be upgraded to this port.

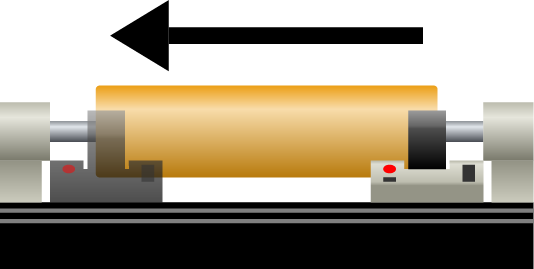

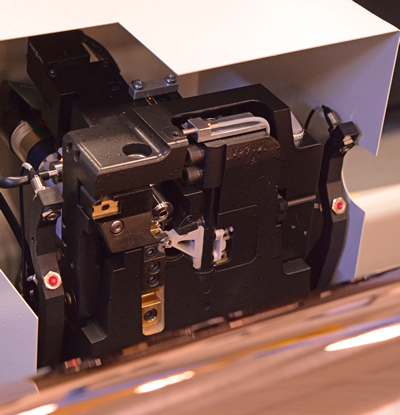

End-Seeking Sensors

New Spectrum and Prism Prime engravers come standard with End-Seeking Sensors for automatic cylinder length verification and placement of engrave head.. The sensors are optical sensors for accuracy. Please contact OHIO or your sales agent to see if your older Spectrum or Prism Prime can be upgraded with the End-Seeking Sensors.

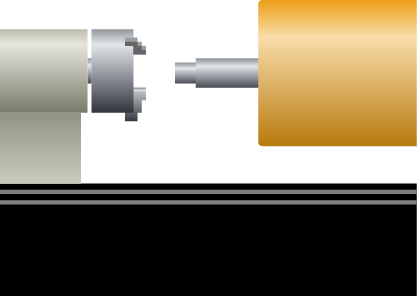

The sensors can be seen on either side of the head (the red dots)

This picture is a close-up, showing the red spot from the sensor on the cylinder.

The sensor itself cannot be seen from this angle.

A close up view of the the end seeking sensor

OHIO listens to our customers and provides unique solutions to your problems. We'd love to talk with you about how we can help you. Contact us!

ABOUT US

OHIO Gravure Technologies in Dayton, Ohio USA designs and manufactures advanced equipment for the global gravure printing market. The Engineering, Software Development, and Manufacturing groups work to provide innovative solutions to improve quality and productivity, such as the award-winning Hybrid Engraving System. Our engineering specialty since 1980 is our sub-micron accurate cutting system (Vision engrave head). We provide installation and support for our electromechanical engravers and the prepress layout software Collage for gravure printing.

21-May-2024

SERVICE

PRODUCTS

CONTACT

Ohio Gravure Technologies Inc

4401 Lyons Road

Miamisburg Ohio USA 45342

phone +1 937.439.1582

email

Follow us on Facebook

Follow us on Facebook